SFS Hinges at Clear Edge

Clear Edge work exclusively with SFS for their door and window hinges. Why? Because SFS are industry leaders and pioneers within their industry – in short, the best.

Quality management, environmental focus and safety management are at the heart of SFS, with an innovative and modest attitude too. At Clear Edge we will only work with like minded suppliers who share our beliefs and meet our standards of quality and care. SFS and Clear Edge are a obvious fit.

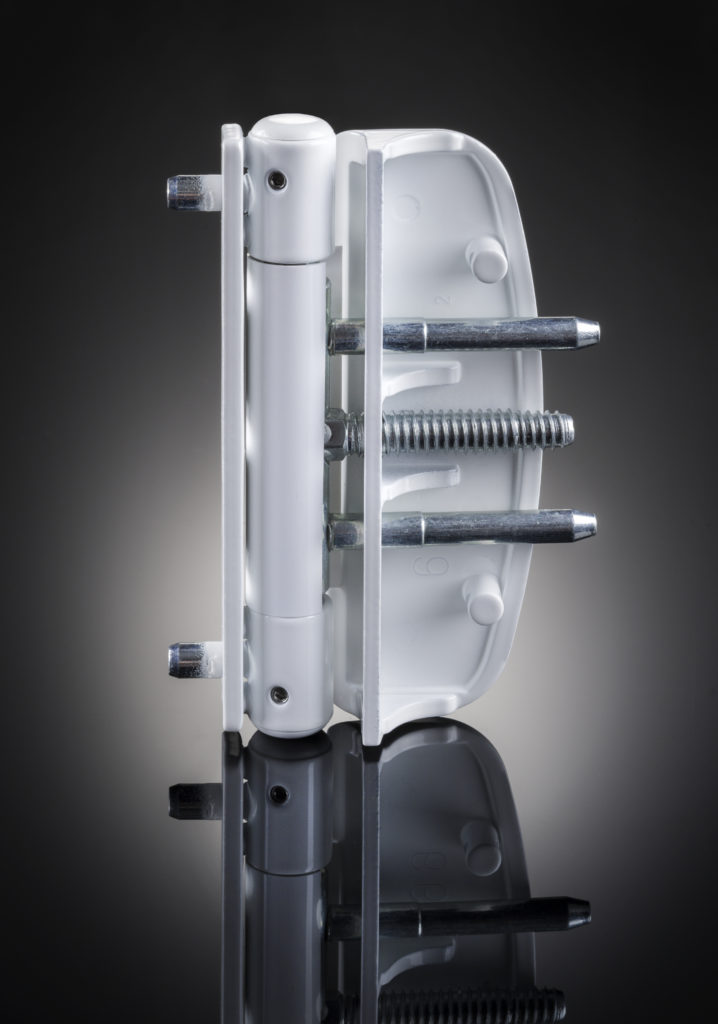

Having recently introduced the 2D hinge, SFS are yet again revolutionising the industry. With its superior aesthetics and performance, their ‘fit and forget’ hinges alleviate work on sagging doors. SFS makes door lifting both safer and simpler.

About the 2D Hinge:

- Leading in aesthetics and performance

- Fit and forget – removes any remedial work on sagging doors

- Custom designed sash plates for all leading profile systems

- Low profile hinge stack, removing the danger of damaging plaster reveals and decorations

- Installation is safer and simpler with door lifting possible

- A single installer can fit with ease

- Fixed gasket pressure

- Dog-bolts are not required

- Constant 4mm adjustment space – no need to adjust top pin in relation to bottom pin

After taking over operations from the British Screw Company limited in 1984, SFS are now a power house in the industry. Despite over 120 years of manufacturing experience in the Leeds factory, SFS now had the task at hand of implementing the most advanced research and development facilities available on the market.

Fast-forward to 2018 and their new partnership, producing carbon and stainless-steel fastening systems for uPVC door and window manufacturers Clear Edge. SFS’s many years of experience in the industry made them the obvious choice for Clear Edge to partner with.

“We cannot thank SFS enough for their support, which has been second to none and has certainly cemented a long-term relationship which expands as Clear Edge grows.”

Chris Palmer; Clear Edge Manager

After establishing a year ago, Clear Edge has joined forces with Green Retreats to solve their uPVC door and window woes.

With uPVCs notorious reputation, Clear Edge have stepped up to take on the challenge of revamping its image, quality and reliability.

Forming a relationship with Green Retreats meant that Clear Edge were able to build bespoke products specifically for garden rooms. Clear Edge went to work on studying all of Green Retreats uPVC concerns, and provided a product second to none.

Only wanting to work with the best, Clear Edge carefully selected a group of suppliers they could trust as a product and company. These suppliers are; Hoppe, Rehau, Carl F Group co, SFS and Quest. In terms of the glass used for Clear Edge products, they were able to develop a strong working relationship with CN Glass and they now have the resources to order glass in various different sizes and models. The quality of the glass used also provides for optimum thermal efficiency. With a minimum standard of SBD and PAS24, security is high on the list for Clear Edge garden room doors and windows.

The Challenge:

Our client, Green Retreats, challenged us to create two bespoke colours and to improve the overall quality of their door and window offering. The result is an 80% drop in door and window snags, increasing efficiency by saving time and money, and also an improved customer experience score.

The Results:

Clear Edge undertook vigorous testing on every aspect of their products, including their two exclusive colours. They tested their durability in terms of the expansion and contraction rates over a period of 12 months.

In a year where we saw the hottest summer on record since 1976, Clear Edge were challenged to reduce snag rates. Despite the heat, snag rates dropped by 80%, and the product delivered what it promised.

Since the development of Clear Edge’s wonder product, Green Retreats have seen a vast improvement in customer satisfaction and reduction in snags.

Wanting to further revolutionise the development and installation process, Clear Edge and their suppliers engineered mechanically jointed doors, allowing for easier site access. The ingenious product is not only practical but maintains all its integrity once installed.

With the production of 80 to 90 sets per week, quality control on all machinery is high on the Clear edge agenda. Yet another nod to their rigour for producing top quality products, manufacturing and distribution.

Clear Edge wants the take all their knowledge on garden rooms and implement it into providing superior quality products for companies such as Green Retreats.

Clear Edge is proving why they’re a force to be reckoned with in the world of PVC-U. With the help of REHAU, Clear Edge want to change the way we view doors and windows.

Construction industry leaders REHAU are now collaborating with Clear Edge to bring both companies passions together to form an unrivalled product, with a combined value for not only high-quality products but also a respect for the environment, with an ecological manufacturing process. A carbon neutral factory powered by a combination of solar power and an incinerator meant that Clear Edge was a perfect partner for REHAU who’s factories run on 100% renewable energy.

Despite being fresh to the industry and with the help of REHAU, clear Edge have already found a noticeable difference in the quality of the products being produces, with a much higher customer satisfaction rate than before. With a factory manager coming from a Formula 1 background, attention to detail is a high priority, all adding to the excellence of the product being produced.

Clear Edge have already seen a high demand in their product, which meant that they also needed a partner who could help them meet the demands. Clear Edge and REHAU look forward to further developing their partnership on a journey which is far from finished and ever-growing.

The name Clear Edge is synonymous with quality – which is why we choose to work with only the best in the industry for every component of our doors and windows. When it came to handles, Hoppe was the clear choice.

Clear Edge have worked closely with Hoppe to design a bespoke range of superior quality handles for our products.